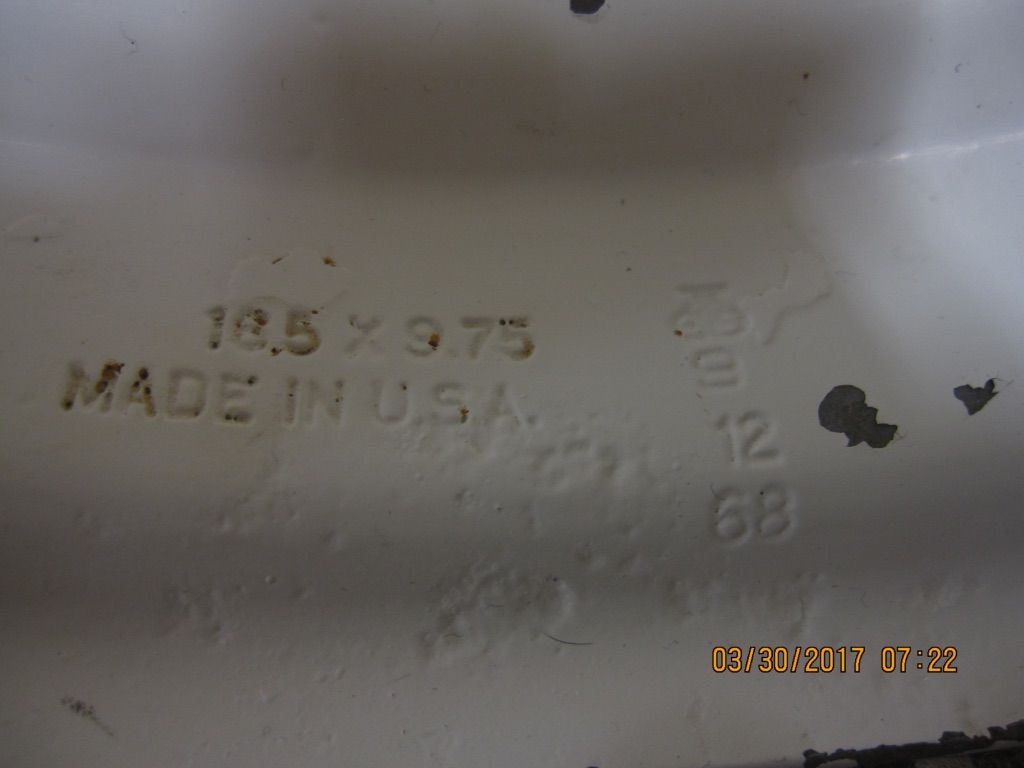

I found a local set of six 16.5 x 9.75 1968 IHC tubeless steel wheels that have our same lug centric 6x7.25 bolt pattern and have a 5-1/2” backspace. They are made by Kelsey Hayes and came from a 1 ton IH truck that has 5/8” wheel studs. I intend to mount a set of Military Goodyear Wrangler MT H1 tires (37 x 12.5 x 16.5 tubeless radials) and run them on my M725. Before I start buying anything for these wheels I want to get your thoughts on this plan . . . . . and also your thoughts on what I see as a potential snag:

The back side of these wheels is stamped and is not flat like the M715/725 wheels – so the contact/handshake with my stock M725 brake drum WMS is different from the stock set-up in a two ways:

1. There are just two circles of contact with the brake drum WMS- an outer stamped raised ridge and an inner stamped flange that you can see in the pics. Once installed, the actual back side of the wheel mounting surface around the wheel stud hole (that’s the area between the stamped ridge and inner stamped flange) is left hanging about 3/16-1/4” away from the drum face. I don’t see how I can get a good/safe connection between the wheel and drum/hub if I tighten these down and I think some/most of that gap will remain- even if I get the 300 ft/lbs of recommended torque. That said, I haven’t tried to tighten them down yet because it seems like it could deform the wheel mounting surface if they are not meant to be squashed down onto a totally flat brake drum? I’m trying to get a pic of the 1968 IH 1300 brake drum WMS that these would have gone on originally so I can see how the handshake between wheel and drum was designed, but haven’t had much luck finding one yet.

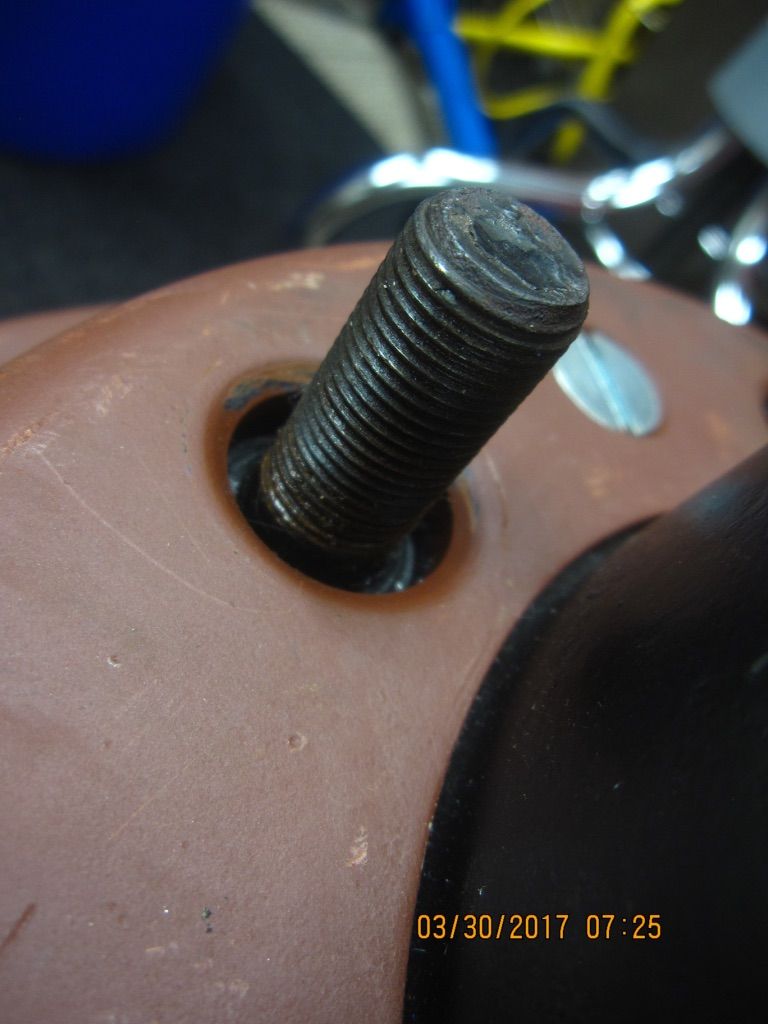

2. The stock M715 wheel mounting surface is mostly flat, but they have an approx 30 degree stamped conical “washer” on the back side that goes into a matching conical recess in the brake drum. See pics below. That conical “washer” fills the larger wheel stud hole on the brake drum - see Pic below. I think that conical washer helps to keep the brake drum from moving around- likely providing way more brake drum rotational support than the three drum machine screws do. Now I know lots of us run recentered wheels with 3/8 and ½ flat plate steel centers that have no conical “washer” to fill that brake drum hole and I haven’t heard that folks have had any problems running that combo so maybe that’s not a fit issue that I need to worry about???

I’m researching how I could fabricate a drop-in conical spacer for each wheel stud that goes between the wheel and brake drum to provide a solution to both these fit issues. I think you can see what I’m thinking about if you look at these, which I’m getting a handful to modify/experiment with: “Misalignment spacers link”

Any thoughts and feedback are appreciated.

Cheers,

Bryce

The wheels:

http://i1108.photobucket.com/albums/...pscmydvewb.jpg

Mounted on M715 hub with M715 drum

http://i1108.photobucket.com/albums/...ps1ey1mg3u.jpg

Reply With Quote

Reply With Quote